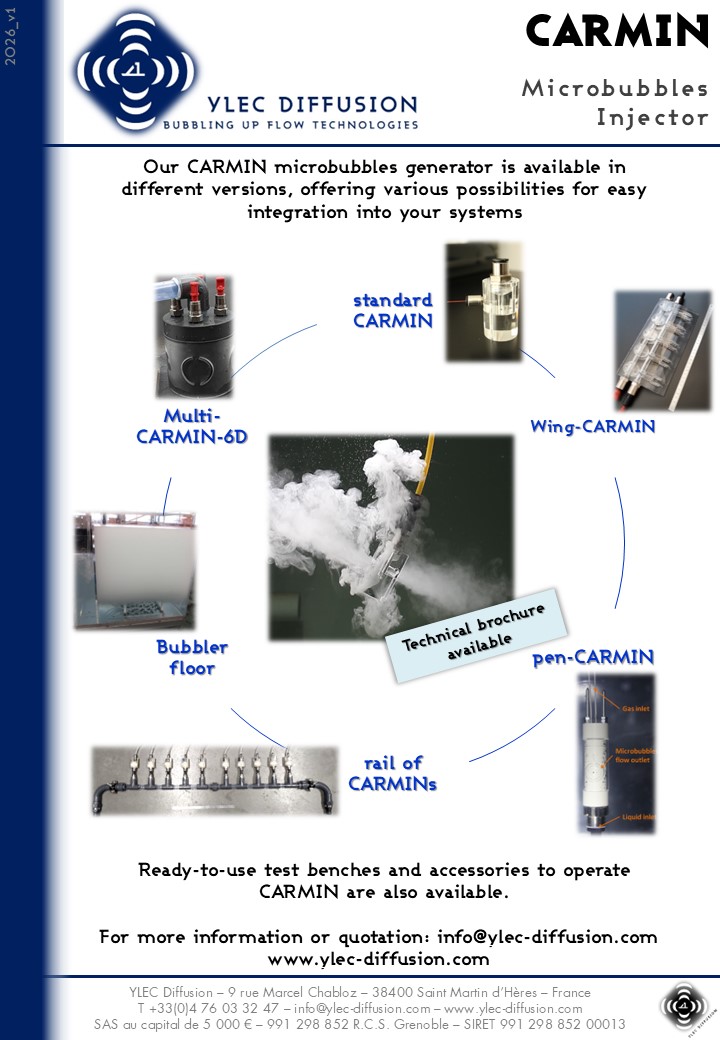

CARMIN Microbubbles Injector

CARMIN microbubbles injector:

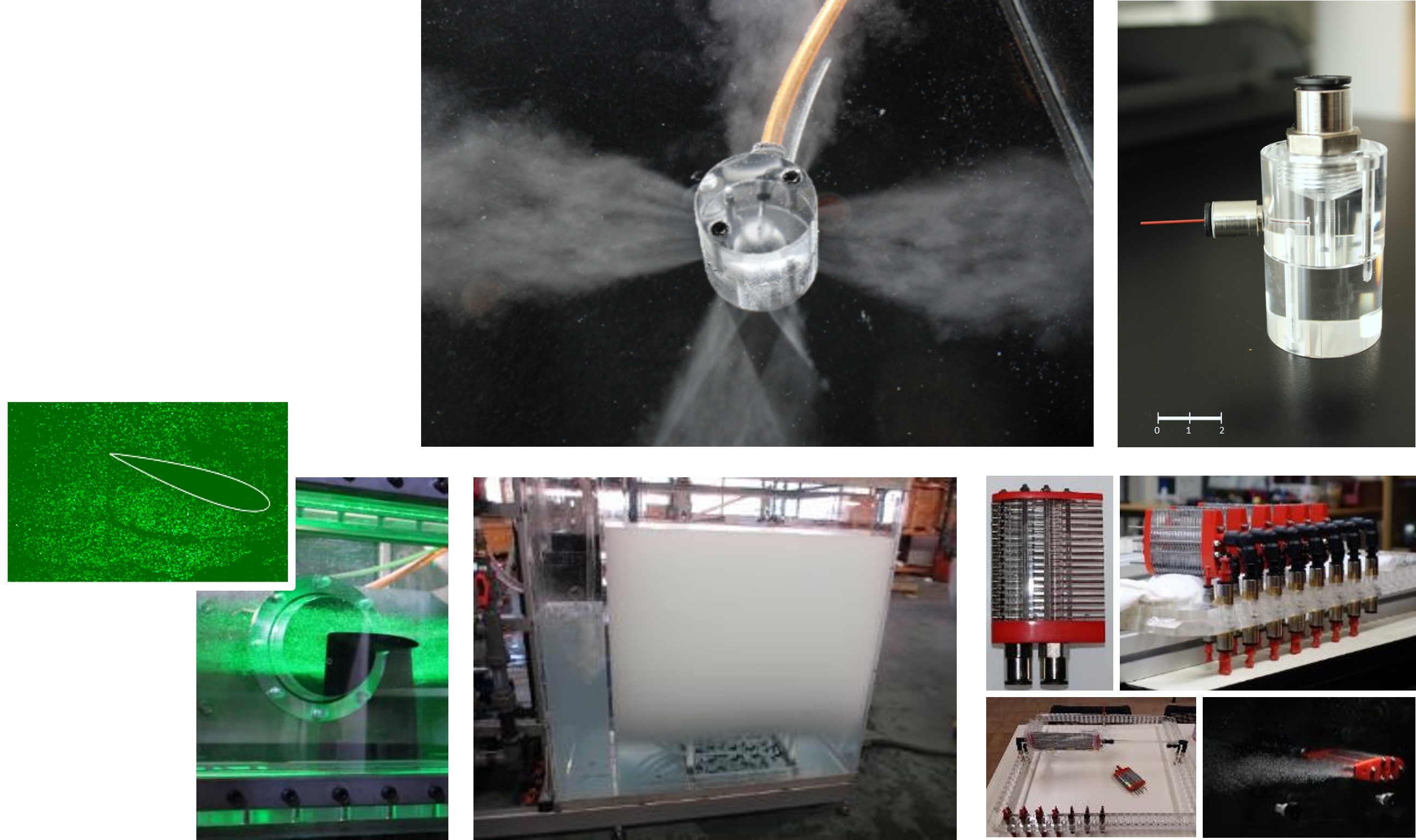

The generation of gas microbubbles by CARMIN generator requires a high pressure water flow to produce a cavitation pocket. A controlled gas flow is then injected into the attached vapor cavity. The gas then breaks up into a cloud of very finely dispersed microbubbles.

Main characteristics:

- Mean microbubbles diameter can be easily adjusted from 20 to 200 µm

- Bubbles maximal production rate is several millions bubbles per second per injector.

- 2 utilizations: atmospheric air suction or gas injection from a pressurized source.

Worldwide shipping (for our standard products, Europe: 2 days / North and South America, Asia, Oceania, Africa: 8 days)

Contact us at info@ylec-diffusion.com

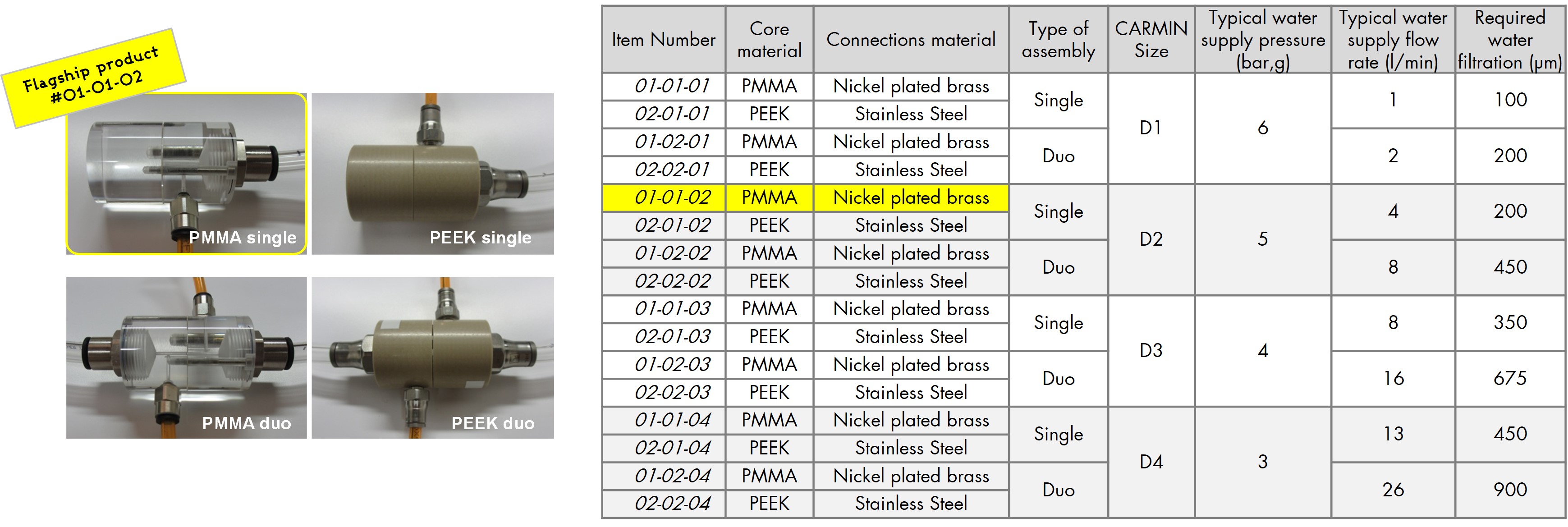

1 technology x 4 sizes x 2 materials x 2 assemblies

= 16 possible combinations to cover various needs

Additional equipment to operate CARMIN generator:

- liquid pump

- water in-line filter

- complete liquid supply line (pump, water in-line filter, manometer)

- complete gas supply line (pressure controller, air filter, manometer)

- spare parts

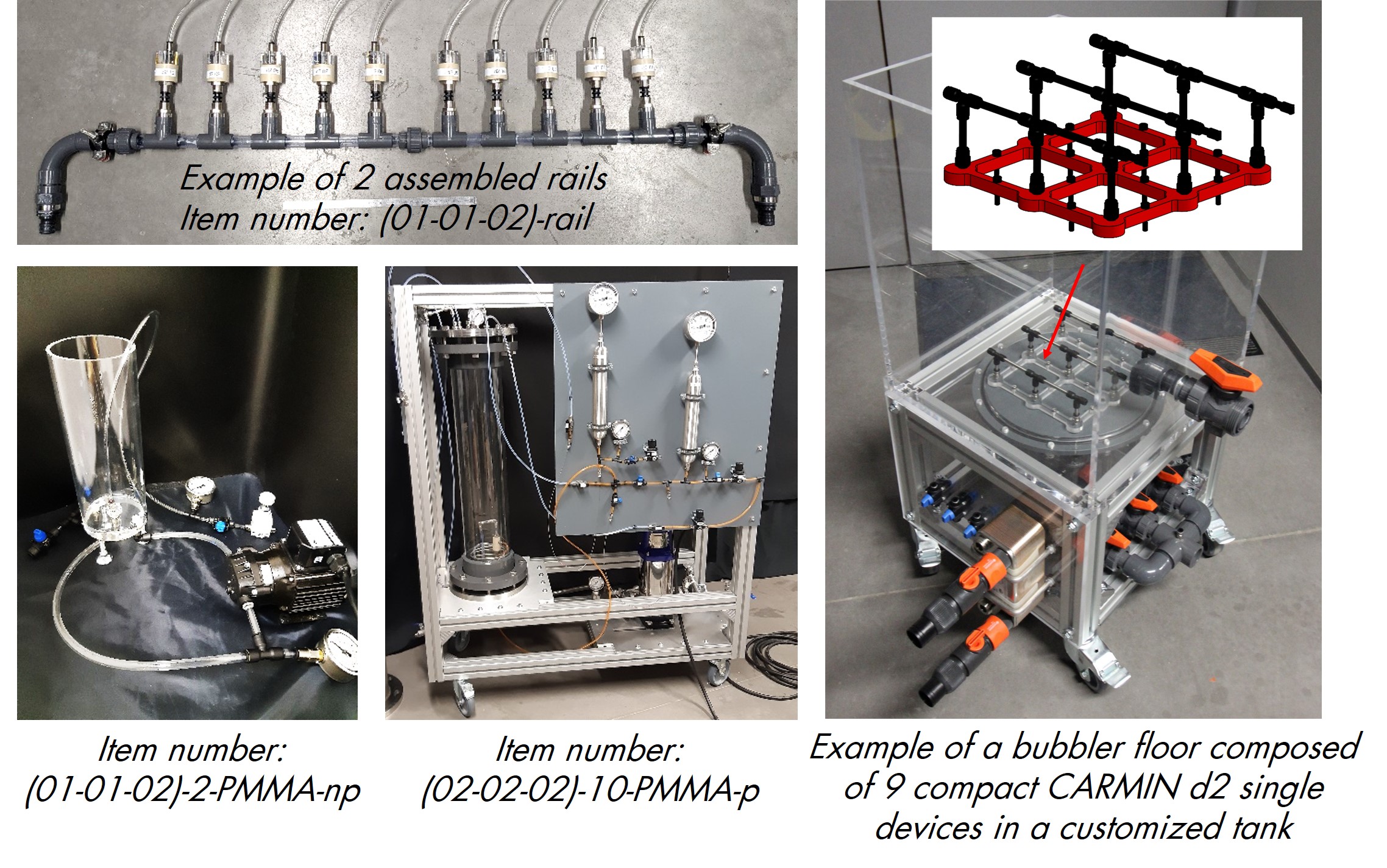

Our other integrated devices and ready-to-use solutions :

- Assembly of CARMIN (rail)

- Exploratory bench integrated CARMIN

- Lab set-up: Similarly to DAF jar tester, this set-up (using CARMIN instead of DAF process) can be used to run preliminary tests to evaluate the influence of bubbles size, coagulants/floculants and ratio between "white water" volume and wastewater volume.

- Custom made "Bubbler floor": To be placed inside column or tank (see picture on the left). Size and integration to be discussed with us (constact us at info@ylec-diffusion.com).

- Wing-CARMIN for velocimetry, PIV/LDV applications

Non-exhaustive examples of application:

Wastewater treatment, Flotation, PIV measurements, Aquaponics/Hydroponics, Oxygenation, Cleaning/disinfection, Ozone injection, Chemical reactions activation, Advanced Oxidation Processes...